BIO INX and Readily3D Announce Collaboration to Advance Volumetric Bioprinting with Cutting-edge Gel-MA Based Ink

BIO INX and Readily3D Announce Collaboration to Advance Volumetric Bioprinting with Cutting-edge Gel-MA Based Ink

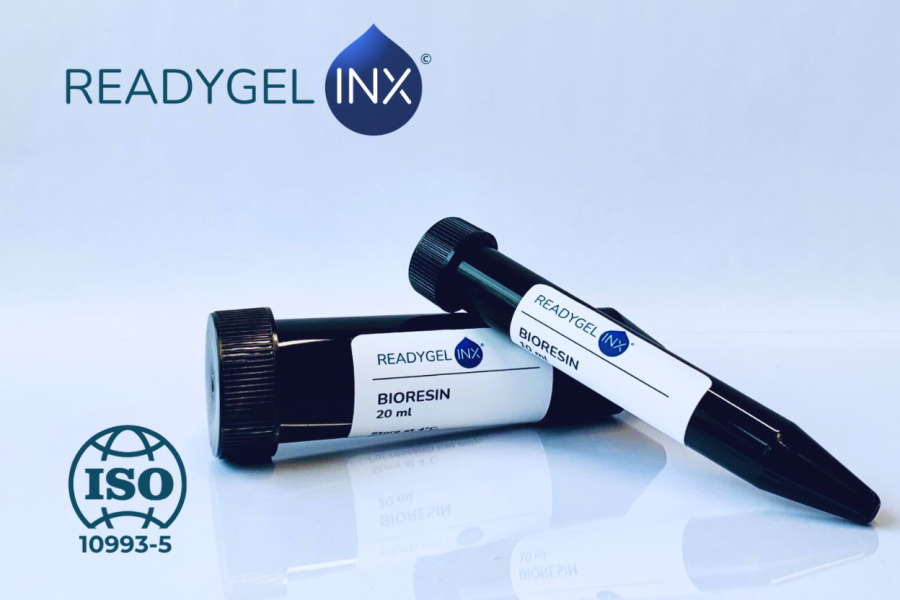

Ghent, 25/05/2024 – BIO INX, a world leader in bioink technologies, is proud to announce its strategic partnership with Readily3D, developer of high-resolution volumetric 3D printers, to introduce new biomaterials for volumetric 3D bioprinting. The first commercially available bioink is a state-of-the-art, gel-MA based ink (READYGEL INX©), designed for high reproducibility and unparalleled performance in volumetric bioprinting applications.

This pioneering ink, which is delivered sterile and ready-to-use, represents the first of a volumetric ink portfolio that will revolutionize the field of bioprinting. Developed to make the user experience as straightforward as possible, READYGEL INX© follows BIO INX’ “plug and print” principle, with preoptimized processing parameters streamlining the bioprinting process and empowering researchers with unprecedented ease of use.

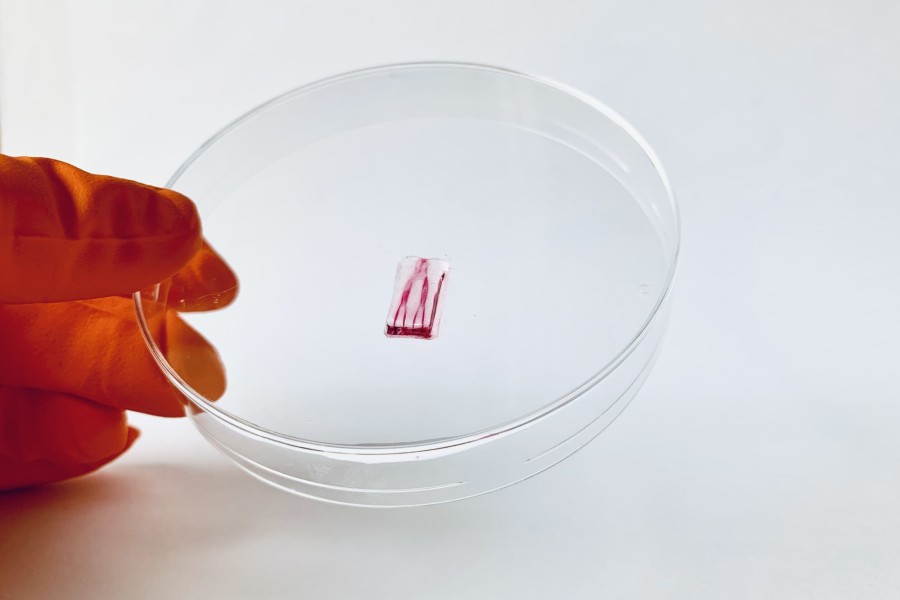

Volumetric printing, a lightning-fast tomographic printing technology, holds the promise of printing structures within seconds, opening a new era of opportunities for clinical applications. “Thanks to the speed of this technology, with the newly developed highly biocompatible resin, the futuristic idea of harvesting cells, printing directly alongside the patient in the operating room prior to reimplantation becomes an attainable reality.” Says Coralie Gréant, COO at BIO INX. By leveraging tomographic 3D printing, which rapidly solidifies photosensitive inks in three dimensions using shaped light beams from multiple angles, centimeter-scale biological systems with microscale resolution can be produced in mere seconds. Importantly, the light-based nature of this printing method ensures minimal shear stress on printed cells, with a low light dose (<600 mJ/cm²), making it exceptionally cell- and organoid-friendly.

CEO of BIO INX, Jasper Van Hoorick, states: "This collaboration perfectly aligns with our vision of bringing bioprinting technology to clinics within the next decade. Prioritizing standardization, reproducibility, and 'turn-key' bioprinting solutions, volumetric bioprinting marks a substantial advancement toward achieving these goals."

Launching this new portfolio with READYGEL INX©, a Gel-MA based resin, comes as no surprise, given that BIO INX originates from the cradle of Gel-MA as a spin off company from the research group where An Van Den Bulcke first published Gel-MA in the year 2000. This research group is currently co-led by prof. Sandra Van Vlierberghe, cofounder of BIO INX. The extensive gelatin expertise at BIO INX is further exemplified by the recent partnership with Rousselot for the distribution of GMP-ready X-pure gelatins.

Paul Delrot, CEO of Readily3D, adds: "Partnering with a reputable supplier of reproducible light-based bioinks aligns with our commitment to delivering comprehensive solutions to our customers. By combining materials with high-reproducibility and high-performance systems, we are accelerating the journey towards clinical applications of bioprinting."

The collaboration between BIO INX and Readily 3D promises to propel the field of bioprinting forward, offering researchers and clinicians groundbreaking solutions to address the challenges of modern healthcare and regenerative medicine.

The new bioink, READYGEL INX©, will officially be presented during the World Biomaterials Conference (WBC) in Daegu, Korea, from May 26th to 31st, 2024. And is available through the webshop of BIO INX at www.bioinx.com or through Readily3D: https://readily3d.com/

About BIO INX:

BIO INX is a pioneering developer of materials for 3D bioprinting, committed to advancing the frontiers of healthcare through innovative solutions. As a spin-out from Ghent University and the Vrije Universiteit Brussel, BIO INX has established itself as a market leader in bioinks for high resolution bioprinting, focusing on materials for both extrusion- and light-based high-resolution printing technologies and offering a diverse portfolio of bioinks for various 3D bioprinting technologies.

About READILY 3D

Readily3D develops and manufactures hardware and software for volumetric 3D printing, respectively commercialized as Tomolite and Apparite to make research in biosciences quicker and more efficient. Founded in 2020, Readily3D originates from a research work started in 2017 at Ecole Polytechnique Fédérale de Lausanne (EPFL). To enable the fast production of complex anatomical structures such as 3D vascular and porous structures,we created Tomolite: a unique bioprinter, allowing biologists to print an entire cell-laden volume at once, in less than a minute and without impairing cell viability.