Bio INX closes its first funding round!

Bio INX announced a capital raise of 700 000 euro from a combination of private investment and public funding. BIO INX is a recent start up focusing on the development and commercialization of bio inks, which are materials suitable for the 3D printing of cells and tissues for 3D bioprinting. In this respect, BIO INX focusses on leveraging their unique expertise to multiple printing technologies by offering equivalent biocompatible materials for three different printing technologies, being extrusion based printing, digital light projection based printing and high resolution laser based printing. The availability of reliable, reproducible materials in the field of 3D bioprinting can be key to bring this technology to the clinics.

The capital raise consists of € 500 000 private investment, which enabled consolidation of a €200 000 euro international grant for the expansion of their portfolio with a completely new product category. This funding round has enabled the installation of state-of-the art research and production labs, enabling the development of next generation bio inks. A first major achievement will be the expansion of their high resolution multiphoton lithography portfolio with the launch of 2 new resins enabling printing of living cells. “This capital raise was crucial to set up our infrastructure to further improve our quality standards and to enable development of our next generation bio inks which will catapult the reach of BIO INX into the market” – Jasper Van Hoorick, CEO of BIO INX. Together with this capital raise, BIO INX will move to their brand new facilities in Tech Lane 66, 9052 Zwijnaarde.

Biofabrication

The world of cell culture, regenerative medicine and biomedical research is changing rapidly. For decades, 2D cell culture in petri dishes has been the standard approach. However, 2D cell cultures often provide an oversimplification of the actual tissue it is trying to mimic. Additionally, it is very difficult to transfer 2D cell culture into regenerative medicine approaches. Therefore, the field of ‘biofabrication’, or the 3D printing of cells and tissues, has emerged as a promising approach to overcome these limitations. While tremendous progress happened in this field in terms of printing technology development, one of the major limitations, is related to the availability of high performing materials or bio inks.

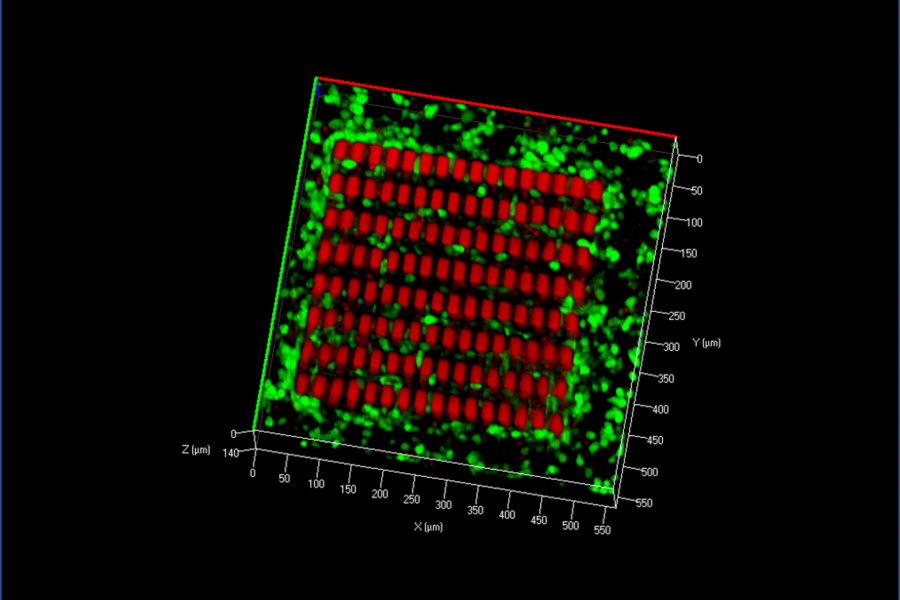

High resolution biofabrication

It is especially in the field of high resolution laser based bioprinting that BIO INX sets itself apart from the competition, as they are unique in developing biocompatible materials which can be processed down to (below) the micrometer. Here, they currently have the only commercial bio ink which enables printing of living cells with this high performing 3D printing technology. This has resulted in partnerships with the 2 marketleaders in the field of multiphoton lithography being Nanoscribe and Upnano. “We believe that this high resolution is crucial to mimic the natural complexity of natural tissues. Additionally, the technology can be crucial for the generation of organ-on-chip systems (i.e. small ‘organs’ on microfluidic chips) for drug development and drug screening purposes” – Agnes Dobos, Application Specialist @ BIO INX. Details on their current bio ink portfolio can be found at www.bioinx.com.