BIO INX and Readily3D Launch READYPCL INX – The First Polyester-Based Resin for Volumetric Bioprinting

BIO INX and Readily3D Launch READYPCL INX – The First Polyester-Based Resin for Volumetric Bioprinting

Breaking new ground in biofabrication: Polyester bioprinting at the speed of light.

Ghent, Belgium / Lausanne, Switzerland – May 19, 2025 – BIO INX and Readily3D proudly announce the launch of READYPCL INX, the world’s first commercially available polyester-based resin for volumetric bioprinting. This innovation marks a significant milestone in the advancement of next-generation bioprinting materials and further cements the collaboration between the two pioneering companies.

The ready-to-use kit comes in 2 volumes: 10 and 20 ml.

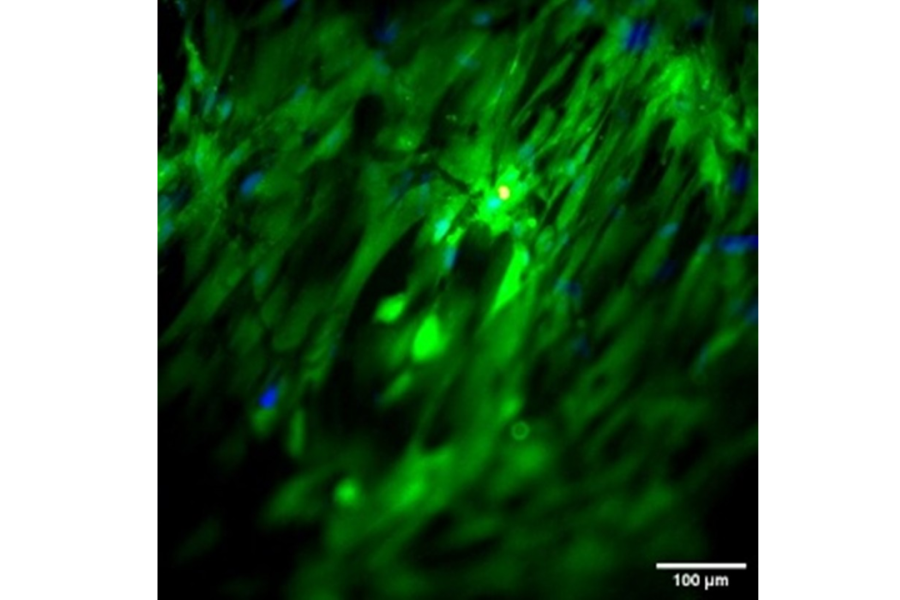

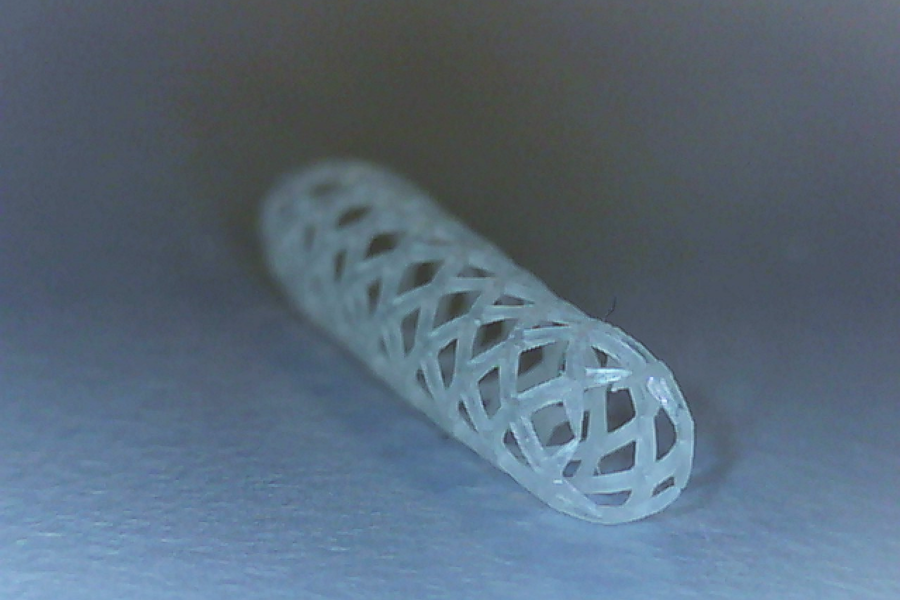

Leveraging the unique capabilities of Readily3D’s Tomolite volumetric bioprinter, READYPCL INX enables the creation of intricate 3D structures within seconds to minutes, with resolutions as fine as 100 µm. Unlike conventional layer-by-layer techniques, this volumetric approach enables the rapid fabrication of complex, load-bearing, and tissue-compatible constructs, pushing the boundaries of what is possible in biofabrication.

“Until now, the majority of materials used for volumetric bioprinting have been gelatin-based,” said Paul Delrot, CEO of Readily3D. “However, demand for alternatives like polyesters has grown rapidly, as they open the door to stiffer, more robust applications such as cartilage and bone tissue engineering.”

READYPCL INX stands out not only for its volumetric printability but also for its biocompatibility (conforming to ISO 10993-5 standards) and full biodegradability. These properties make it ideal for a wide array of biomedical applications, including regenerative medicine, tissue engineering, and clinical research.

“The development of READYPCL INX was a logical next step for us,” said Aysu Arslan, CSO of BIO INX. “This resin builds upon our proprietary chemistry platform, already proven in materials like SOLID INX (extrusion), DEGRES INX (DLP), and DEGRAD INX (multiphoton lithography). Bringing this robustness to the high-speed realm of volumetric printing is tremendously exciting.”

The introduction of READYPCL INX significantly expands the BIO INX material portfolio across bioprinting platforms and underlines the growing synergy between BIO INX and Readily3D. Both companies share a vision of making high-speed, in-situ bioprinting a clinical reality.

“Volumetric bioprinting is one of the most promising breakthroughs in 3D bioprinting—and even in 3D printing at large,” added Jasper Van Hoorick, CEO of BIO INX. “Its non-layered approach, combined with exceptional speed and reproducibility, brings us closer to operating-room bioprinting. The idea of printing replacement tissues like cartilage or bone directly during surgery is becoming increasingly feasible thanks to materials like READYPCL INX.”

READYPCL INX will be officially unveiled to the broader scientific and medical communities at the 2025 TERMIS-EU conference from May 20 to 24 in Freiburg, Germany.

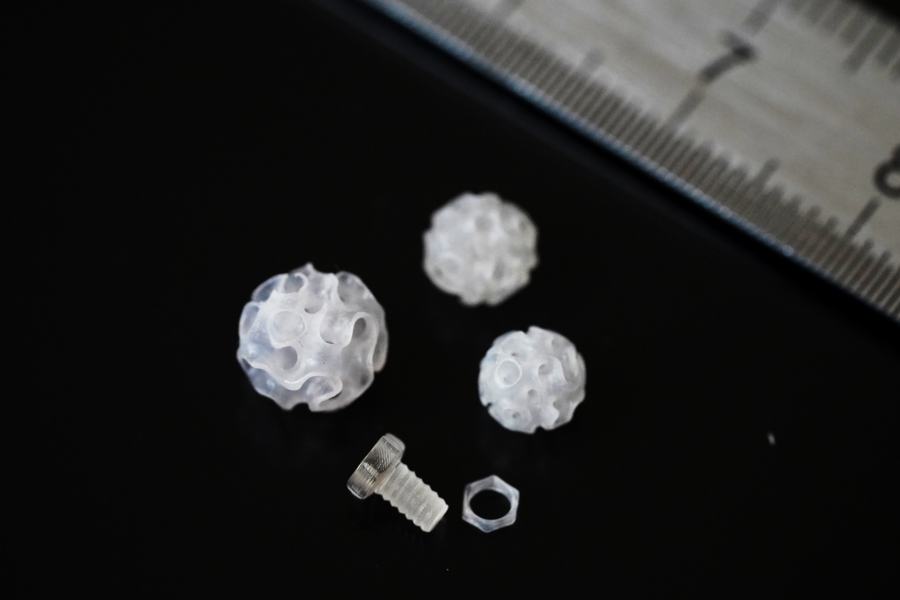

Printed structures using READYPCL INX including a functioning nut and bolt, printed on the Readily3D Tomolite v2.0

Readily3D and BIO INX team members at the 2024 World biomaterials conference from left to right: Max Kollep (Readily3D), Paul Delrot (Readily3D), Aysu Arslan (BIO INX) and Jasper Van Hoorick (BIO INX)

About BIO INX:

BIO INX is a pioneering developer of materials for 3D bioprinting, committed to advancing the frontiers of healthcare through innovative solutions. As a spin-out from Ghent University and the Vrije Universiteit Brussel, BIO INX has established itself as a market leader in bioinks for high resolution bioprinting, focusing on materials for both extrusion- and light-based high-resolution printing technologies and offering a diverse portfolio of bioinks for various 3D bioprinting technologies.

Contact:

Jasper Van Hoorick

CEO, BIO INX

E : Jasper.vanhoorick@bioinx.com

T : +32 499 16 98 94

About READILY 3D

Readily3D develops and manufactures hardware and software for volumetric 3D printing, respectively commercialized as Tomolite and Apparite to make research in biosciences quicker and more efficient. Founded in 2020, Readily3D originates from a research work started in 2017 at Ecole Polytechnique Fédérale de Lausanne (EPFL). To enable the fast production of complex anatomical structures such as 3D vascular and porous structures, we created Tomolite: a unique bioprinter, allowing biologists to print an entire cell-laden volume at once, in less than a minute and without impairing cell viability.

Contact:

Paul Delrot

CEO, Readily3D

T : +41225701483

https://readily3d.com/