BIO INX, Puredyne, and AM Technologies by Brinter Unite

BIO INX, Puredyne, and AM Technologies by Brinter Unite to set new Standard in Extrusion Bioprinting.

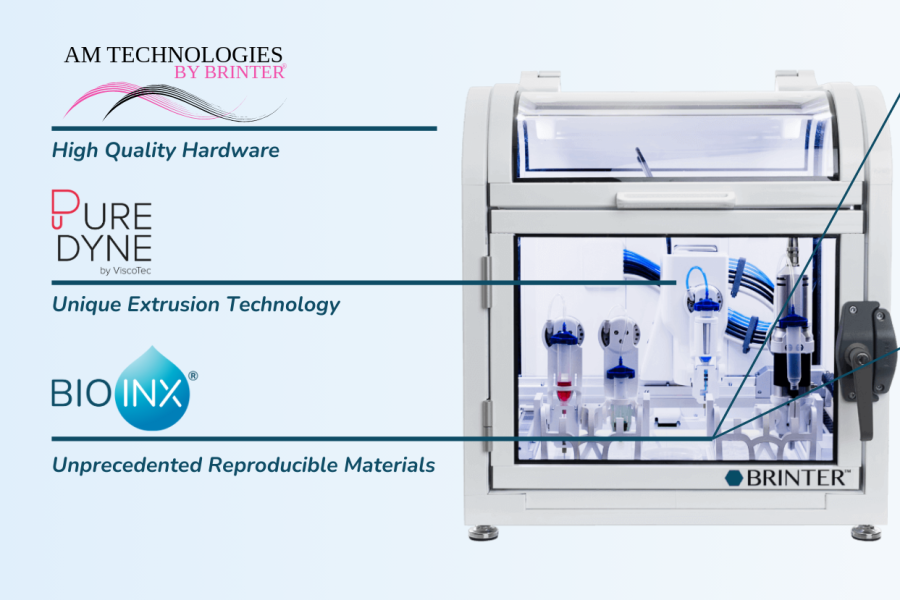

Ghent, Belgium – 20/11/2024 – BIO INX, a leader in advanced bioinks, Puredyne, a pioneer in extrusion printhead technology, and AM Technologies by Brinter, an innovator in bioprinter manufacturing, are proud to announce a groundbreaking collaboration aimed at achieving unparalleled standardization and reproducibility in extrusion-based bioprinting.

This partnership builds upon the existing collaboration between BIO INX and Puredyne to enhance extrusion bioprinting by combining BIO INX’s highly reproducible bioinks with Puredyne's unique extrusion technology. Specializing in gelatin-based inks, BIO INX’s expertise stems from two decades of innovation in gelatin modification—dating back to the pioneering 2000 publication of gel-MA—the company has honed strict quality management systems (QMS) to produce high-quality, standardized bioinks. On top of that, it relies on a strong collaboration with Rousselot, one of the leading gelatin manufacturers resulting in reproducibility from the raw material level until the final ink.

Puredyne contributes its cutting-edge extrusion printhead technology, enabling effortless and consistent extrusion of bioinks across an unprecedented range of viscosities. These unique printheads have become essential for ensuring reliable bioprinting processes.

From left to Right: Felix Gruber (Puredyne), Tomi Kalpio (Brinter AM Technologies), Jasper Van Hoorick (BIO INX)

Completing the puzzle

To complete the puzzle, AM Technologies by Brinter brings advanced bioprinter manufacturing expertise, offering exceptional levels of control and standardization. AM Technologies by Brinter’s state-of-the-art solutions, including the bioprinter designed for use on the International Space Station, exemplify the high-performance systems needed to meet the collaboration's ambitious goals.

“Reproducibility is the cornerstone of advancing bioprinting technologies. At Puredyne, we are proud to bring our innovative extrusion printhead technology to this partnership, ensuring bioinks can be processed reliably across a spectrum of viscosities. Working with BIO INX and AM Technologies by Brinter elevates our mission to set new benchmarks for bioprinting.” -Felix Gruber, Puredyne

The culmination of this shared vision is the integration of Puredyne’s heated printhead module into AM Technologies by Brinter’s Brinter One and Brinter Core bioprinting systems, setting a new standard for extrusion bioprinting technology.

“At BIO INX, we have the mission to bring biofabrication to the clinic, and in our opinion, the only way to get there is through smart collaborations between complementary companies. Together with Puredyne and AM Technologies by Brinter, we are addressing the critical need for standardization and reproducibility in bioprinting, paving the way for broader adoption in clinical and research settings.” -Jasper Van Hoorick, CEO at BIO INX

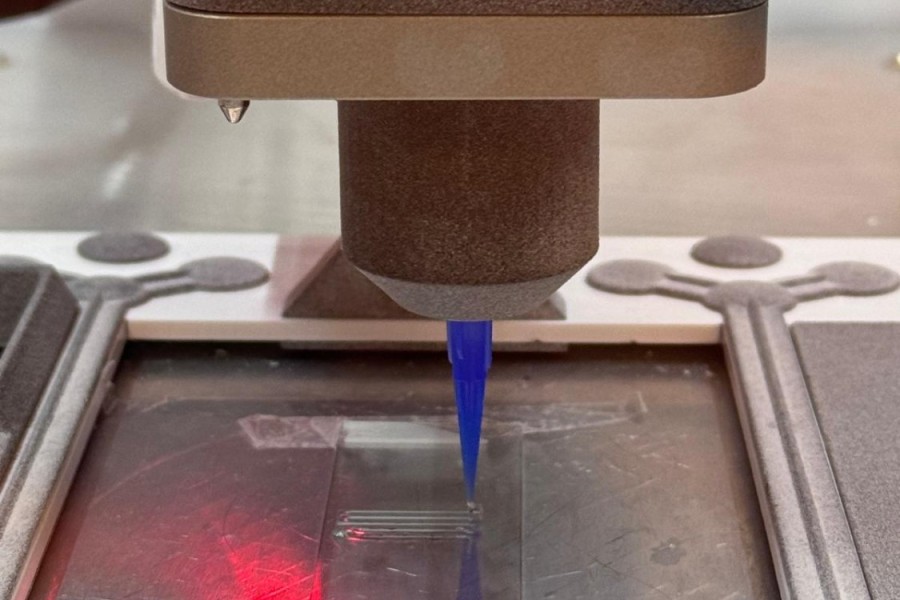

Tall gelatin structure printed using the unique combination of the Brinter one system with the new Puredyne heated printing module using the Gel-MA INX X100 ink from BIO INX.

About the Collaboration

“Bioprinting solutions need to deliver not just innovation but also unmatched precision and reliability. At AM Technologies by Brinter, we are thrilled to combine our expertise with BIO INX and Puredyne to develop systems that empower researchers and clinicians alike. This collaboration represents a significant leap toward making biofabrication accessible and impactful on a global scale.” – Tomi Kalpio, CEO at AM Technologies by Brinter (Formnext hall 11.1 booth B69 Finnish pavilion);

This partnership represents a fusion of expertise: BIO INX’s leadership in bioink development, Puredyne’s technological advancements in extrusion, and AM Technologies by Brinter’s high-performance bioprinting systems. Together, the three companies are setting new standards for extrusion bioprinting, enabling consistent and reproducible results for a variety of applications, from research to clinical use.

Discover all about this collaboration at Formnext in Frankfurt at the booth of Puredyne (hall 12.1 booth F119).

Printing of the gelatin based ink using the new Puredyne printhead on the Brinter One system.

About BIO INX:

BIO INX is a pioneering developer of materials for 3D bioprinting, committed to advancing the frontiers of healthcare through innovative solutions. As a spin-out from Ghent University and the Vrije Universiteit Brussel, BIO INX has established itself as a market leader in bioinks for high resolution bioprinting, focusing on materials for both extrusion- and light-based high-resolution printing technologies and offering a diverse portfolio of bioinks for various 3D bioprinting technologies.

Contact:

Jasper Van Hoorick

CEO, BIO INX

E : Jasper.vanhoorick@bioinx.com

T : +32 499 16 98 94

About Puredyne

Puredyne represents printheads that combine the proven ViscoTec dispensing technology with single-use cartridges. Thanks to the endless piston principle, Puredyne enables volumetric dispensing - regardless of viscosities and is particularly gentle. The new brand was created in 2021. The areas of application of the printheads include the fields of bioprinting and regenerative medicine, with plans to expand to other industries. Puredyne is a brand of ViscoTec Pumpen- u. Dosiertechnik GmbH. ViscoTec mainly deals with systems required for conveying, dosing, applying, filling and emptying medium to high-viscosity material. The headquarters of the technological market leader is located in Töging (Upper Bavaria, Altötting district, Germany). ViscoTec also has subsidiaries in the USA, China, Singapore, India, France and Hong Kong and employs around 330 people worldwide.

Felix Gruber

Business Development Single Use, Puredyne

T: +49 8631 9274-235

About Brinter AM Technologies

Brinter AM technologies is a trailblazer in additive manufacturing, specializing in advanced bioprinting technologies. Their modular 3D bioprinting solutions empower researchers and industry professionals to create complex, high-precision structures for tissue engineering, drug development, and regenerative medicine. With a strong focus on versatility and scalability, Brinter’s innovations are driving the future of personalized healthcare and biomedical advancements.

Contact:

Tomi Kalpio

CEO, Brinter AM technologies