Fastest High-Resolution 3D (Bio)Printer Ever Reported uses BIO INX Resins in its First Trials.

BIO INX proudly announces a breakthrough in high-resolution 3D bioprinting with the use of DEGRAD INX U100, the world’s first polyester-based biodegradable resin, in a pioneering new two-photon polymerization (2PP) system. This revolutionary technology, developed by the PhD student Stefan Binder in the research group led by prof. Aleksandr Ovsianikov at TU Wien, has set a new benchmark as the fastest 3D printer ever reported, demonstrating a paradigm shift in the field of Biofabrication with a 58 fold increased throughput.

The video shows the live printing speed of multiple microscaffolds in parallel in the DEGRAD INX U100 resin at scanning speeds of up to 66m/s!

Two-photon polymerization (also known as multiphoton lithography) is an advanced laser-based 3D printing technique that enables the fabrication of microscopic structures with extreme high resolution, even down to subcellular precision. By using a powerful laser and high-resolution focusing optics, this technique selectively polymerizes photosensitive materials at the focal point of the laser, allowing for the creation of complex 3D structures with extreme accuracy. Historically, the speed of this technology has been a major limitation—until now.

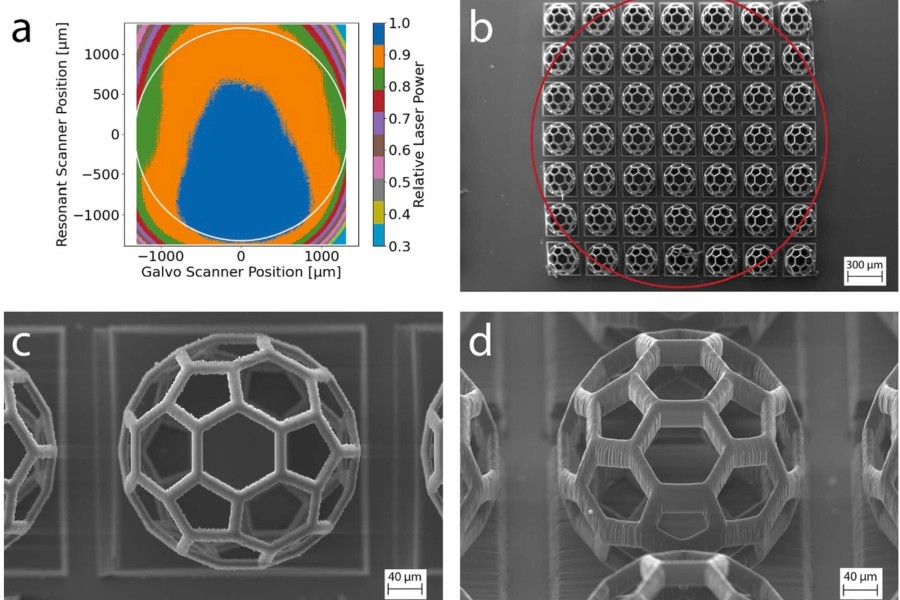

This latest innovation incorporates a resonant scanner, replacing conventional galvanometer mirrors, to dramatically increase fabrication speed. Unlike previous systems where laser positioning was limited by the movement of galvo mirrors, the resonant scanner enables rapid oscillation of the laser beam, significantly enhancing throughput without compromising resolution. By precisely controlling the laser’s focus at ultrafast speeds, entire layers of a 3D construct can be drawn efficiently. The optics then shift layer by layer, enabling the fabrication of intricate 3D microstructures at unprecedented rates.

Figure 1: The image shows the printed microscaffolds using the fastest high resolution 3D printer.

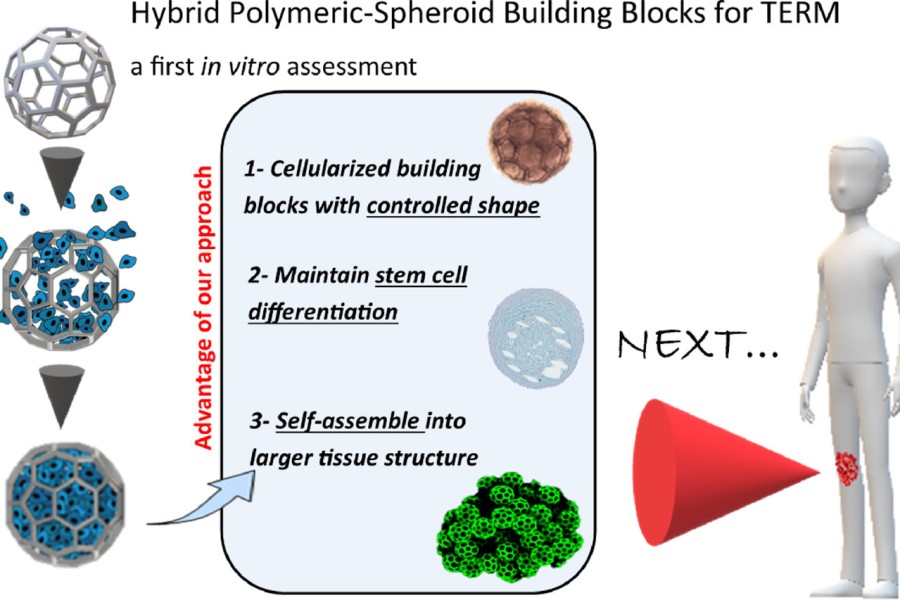

One of the most promising applications of this technology lies in tissue engineering. A few years ago, Professor Aleksandr Ovsianikov from TU Wien introduced the concept of printing microscopic cellular cages, which can be injected into tissue defects and filled with living cartilage cells which he refers to as ‘the third strategy in tissue engineering’ (see Figure 2). However, the challenge has always been the scalability of this approach—producing enough cages to fill substantial tissue defects was simply too slow with existing technology. Now, thanks to the high-speed capabilities of this new 2PP system, large-scale production of these microscopic cellular scaffolds becomes feasible, with a maximum production of 208 microscaffolds/h using galvo scanners, this resonant scanner based printers now increases this to 12078 microscaffolds/h bringing the third strategy of tissue engineering—injectable biofabricated constructs—closer to clinical reality.

Figure 2: The figure demonstrates the principle of this 'third strategy of tissue engineering' where cell-laden microstructures are printed to be injected into the site of tissue defect. There they will merge while the printed cages are degraded to form healthy cartilage without cell death of the injected cells. (image reprinted from: https://doi.org/10.1016/j.actbio.2022.03.010)

BIO INX’s DEGRAD INX U100 resin played a crucial role in validating this new printing technology. Designed for high-resolution biofabrication, this biodegradable material supports cell compatibility while enabling the fabrication of ultra-fine structures essential for tissue engineering. Beyond bioprinting, the new high-speed 2PP system also has potential applications in micro-optics, photonics, and electronics, where precision manufacturing at microscopic scales is essential.

With the potential of printing up to 12078 microscaffolds per hour (in contrast to the previous record of 208 microscaffolds per hour), suspensions with these tiny structures almost resemble snowflakes dancing around in the solution.

This achievement represents a major step forward in 3D bioprinting, paving the way for innovative biomedical applications and beyond. Congratulations to Stefan Binder and his colleagues for pushing the boundaries of what is possible in additive manufacturing.

Read the full publication here:

https://www.sciencedirect.com/science/article/pii/S221486042400647X

All images reproduced from: https://doi.org/10.1016/j.addma.2024.104601

Movies courtesy of TUWIEN

Find our more about DEGRAD INX here: https://bioinx.com/products/degrad-inx

Want to learn more about the historical technological breakthroughs in multiphoton lithography, then check out our review we published in 2023:

https://advanced.onlinelibrary.wiley.com/doi/abs/10.1002/adfm.202212641